Ultrasonic flaw detector

Ultrasonic flaw detector

In 1993, our company cooperated with the Institute of Acoustics of the Chinese Academy of Sciences to successfully develop the first UFD-GA ultrasonic flaw detector for gear welds. Up to now (as of December 2011), more than 80 ultrasonic flaw detectors of various types have been sold.

In 2000, based on the experience of users, we jointly designed the second generation of UFD-GB ultrasonic flaw detector for gear welds.

In 2004, we jointly designed a new generation of UFD-GC ultrasonic flaw detector for gear welds.

In 2005, we jointly designed the UFD-GW ultrasonic flaw detector for gear welds, which is mainly used for ultrasonic flaw detection of complex gears of automobile automatic transmission and welds of planetary gear carrier.

UFD-GC-2 efficient gear ultrasonic flaw detector (with flaw detection efficiency ranging from 160 pieces/hour to 220 pieces/hour) and ultrasonic flaw detector for other purposes are also introduced.

UFD-GC ultrasonic flaw detector for gear welds

UFD-GC ultrasonic flaw detector for gear welds

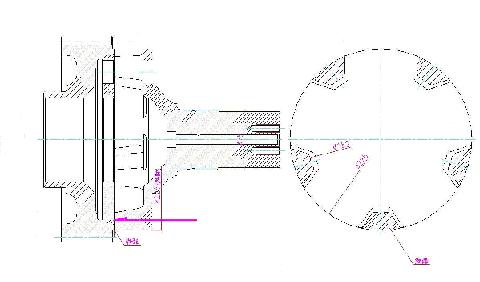

The flaw detector is mainly used to check the weld defects of automobile gears (such as cracks, air holes and insufficient welding depth *). The detected gear is placed in the flaw detection water tank, the gear rotates, and the focused ultrasonic pulse beam scans the weld area. At the same time, the color weld schematic diagram and sound beam track are displayed on the display. The defective area and the good welding area are marked with different colors. After scanning the weld, the instrument automatically calculates the percentage of defects in the total weld length, automatically judges according to the given flaw detection standard, and displays the judgment results. Except for parts loading and unloading, all operation processes are automatically completed under the control of the computer.

The industrial control computer of this equipment can also record all flaw detection data to form a file, which is convenient for enterprises to realize networking and remote management.

Main technical indicators

1、Host:

Ultrasonic channel: 2

Frequency range: 5-25 MHz, select the appropriate frequency according to the specific conditions of the tested gear;

Transmit pulse:≥250V,≤7 nS

Computer configuration: Kurui 2, 2.4G CPU, 1GB DDRAM, hard disk above 500G; 19 inch wide screen LCD

2、Types of detectable workpiece: disc gear, shaft gear;

3、Workpiece size: inner diameter ≥ φ 24mm, outer diameter ≤ φ 240mm;

4、Flaw detection sensitivity: for general small gears Φ 0.5 flat bottom hole equivalent (same as FIAT standard); The specific requirements shall be proposed by the user in principle and determined by both parties through consultation;

5、Rejection standard: determined according to the percentage of the total length of defects exceeding the reference sensitivity in the total length of the weld; The grading standard proposed by the user can be displayed in several grades;

6、Wall thickness of workpiece: 3-18 mm (flaw detection sensitivity may vary with different wall thicknesses)

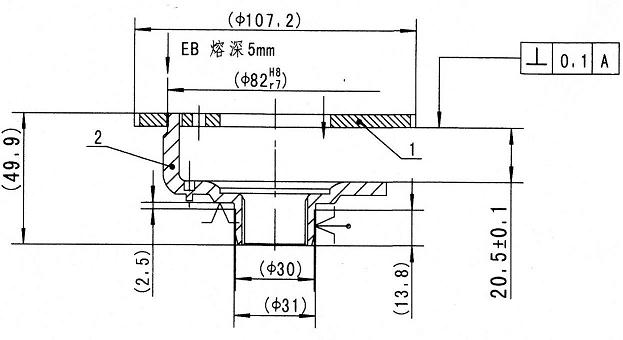

7、Weld depth: 2~10 mm (the flaw detection method and sensitivity may be different for different weld depths, so the productivity, equipment and price may be different);

8、Detection efficiency: up to 80 pieces per hour (small gears)

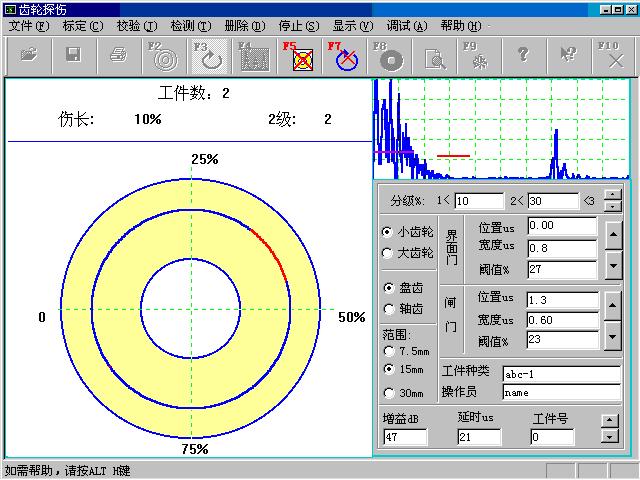

9、Display mode: real-time display of weld seam, sound beam track and defect diagram on 19 inch wide screen LCD, and display the judgment results (Figure 2);

10、Man machine interface: graphical Chinese character interface;

11、Archive: the flaw detection results are stored in a large capacity hard disk (no less than 500GB) for easy management;

Convenient flaw detection data query, statistics and report functions;

12、Automatic rise and fall of water level: the water level drops automatically after detecting a workpiece, which is convenient for loading and unloading;

13、Operating condition: can work continuously for 24 hours

14、Source: AC220V±10%, 50Hz, 2KVA

15、Operating environment: 10~30 ℃, no corrosive gas and dust, and compressed air is required;

16、Weight (about): 350KG

17、Overall dimension: 1000 × six hundred × 1500 (long × wide × High)

18、Print function: support printer output.

Flaw detection standard:

For small car gears, the default state of this equipment is Italian FIAT gear weld flaw detection standard.

Display interface:

Live picture:

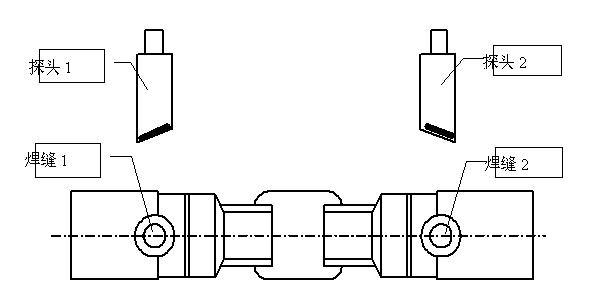

UFD-GW/SCW type (oblique) ultrasonic flaw detector for welds of planetary gear carrier

UFD-GW/SCW type (oblique) ultrasonic flaw detector for welds of planetary gear carrier

Purpose::

It is mainly used for ultrasonic flaw detection of electron beam welds of planetary gear carrier of heavy trucks and complex gears of automatic transmissions.

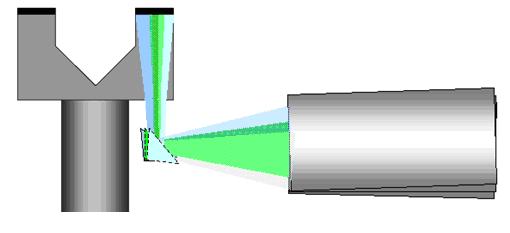

UFD-T ultrasonic flaw detector for automobile turbocharger weld

UFD-T ultrasonic flaw detector for automobile turbocharger weld

Flaw detection sensitivity: up to 1 mm2 (monitoring contrast damage φ 1.1 Flat bottom hole) (adjustable according to actual needs).

Graphics and Chinese characters display: graphics include operation interface, real-time display of ultrasonic waveform, and ultrasonic image display.

Production rhythm: up to 100 pieces/hour.

Working system: 3 shifts per day.

UFD-P/CW1 ultrasonic flaw detector for piston weld of automobile air conditioner

UFD-P/CW1 ultrasonic flaw detector for piston weld of automobile air conditioner

Purpose::

It is specially used for ultrasonic flaw detection of electron beam weld of automobile air conditioning compressor piston.